What you always wanted to know about precious metals and their properties!

Did you know that precious metals have many properties that can be very different?

How so? Properties that make the metal different?

Just like we humans are different, every metal is different and we can use them in many different ways.

For jewellery we usually use the precious metals silver, gold and platinum.

A precious metal is a metal that barely reacts chemically with other substances and is therefore resistant to corrosion and oxidation.

Why do jewels not consist of 100% pure gold or silver?

In their pure form, precious metals can be worked very easily. They have a certain softness, but that same softness also makes them more vulnerable to wear. For this reason, we mix them with another metal so that they harden and do not wear out as quickly – this is called an alloy.

What is an alloy?

An alloy is a combination of two or more metals that are fused together to form a single homogeneous mass.

In the making of an alloy, the different metals undergo changes in their hardness, colour, melting point, density and price (value).

What is the specific gravity/density of metal?

The specific gravity or density indicates how much a material weighs. This is indicated by comparing how many times a certain volume of the substance in question is heavier than the same volume of water at 4°C.

Pure gold has a specific gravity of 19.2 kg/dm³, silver 10.5 kg/dm³.

The density of metal can be adjusted, as it depends on the purity and processing of a metal. For example, rolling and forging a metal may increase the density, while wire drawing may reduce it.

Are the melting and casting temperatures of metal the same?

The melting temperature or melting point is the point at which the metal passes from its solid state to its liquid state and vice versa. The casting temperature of a metal is a little higher, so that the metal stays in its liquid state even if it cools down slightly.

Did you know that the melting point of different metals can be very different? The melting point of gold is 1064°C, of silver 962°C while the melting point of tin for example is only 232°C.

How do we forge metal?

Toughness is the attraction or cohesion of the atoms of an alloy between different metals. This means that the tougher a material is, the more load it can take without breaking, although the material will deform plastically before breaking anyway. We can increase or decrease the toughness by using other metals in the alloy.

The hardness of a substance is characterised by its resistance to penetration by another substance or its resistance to permanent deformation. Two identical alloys thus scratch each other to the same degree. The choice of alloy plays a major role for the various components of a piece of jewellery. The hardest commonly known mineral is diamond.

The malleability of a metal tells us how well it can be worked by hammering or crushing.

The ductility tells us how easily the metal or alloy can be drawn into certain profiles, the diameter is reduced and the metal becomes longer.

Is annealing the same as melting?

When we anneal a metal, it means that we heat it strongly without melting it. By annealing and then slowly cooling down, the crystals inside the metal become larger. The size of the crystals can be reduced by hammering, rolling and drawing. If we reduce the size of the crystals, the hardness increases – which can be compensated for by annealing.

How is precial metal melted?

For each different metal, we use a different crucible to melt the metal with our burner.

There are open and closed crucibles for casting our precious metals.

The crucible is placed in a metal holder for easy pouring of the metal.

When melting, it is important to reach the right temperature for the melting: as soon as the melted metal gives the impression of a mirror (egg), it can be cast. The casting temperature is about 50-100°C above the melting point, depending on the quantity being melted.

When can we pour our precious metal from the crucible into the cast iron?

If we cast the metal too cold, it will not be a thin liquid and the trapped gases will have difficulty escaping. It is therefore better to cast too hot, as this works better and the quality of the product will also be better. Of course, we should not overheat either, because this will cause evaporation and burning of the metal. If the metal is overheated, there will also be too much movement during the cooling process in the mould, which may result in undesired crystal forms and cracks when we want to further process the precious metal.

Can we just melt different metals together?

As the different metals have different melting points, this has to be taken into account.

When making an alloy – which we melt in a crucible – the metal that is hardest to melt (has the highest melting point) is melted first and then the metals with a lower melting point are added.

Only by carefully adhering to the order of decreasing melting points do we obtain a homogeneous mass and prevent burning.

What are the most commonly used precious metals in jewellery?

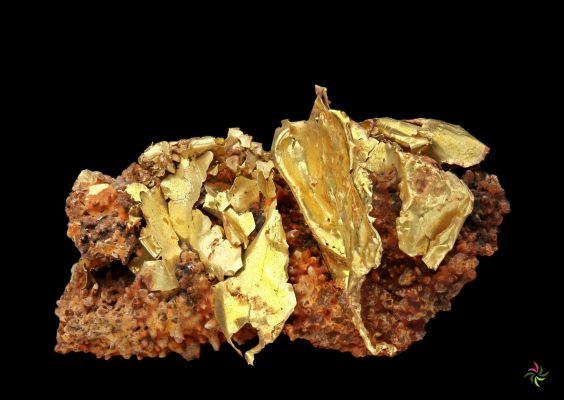

Gold

Gold – also known as Aurum (Au) – is a precious metal with a melting point of 1064°C and is a very good conductor of heat or electricity.

Pure gold or fine gold is a fairly soft metal and does not oxidise, and in its pure state it is the most crushable of all metals (very malleable), something that is especially useful when making gold leaf. Gold also has a high elasticity, which means that one can draw extremely long threads from gold.

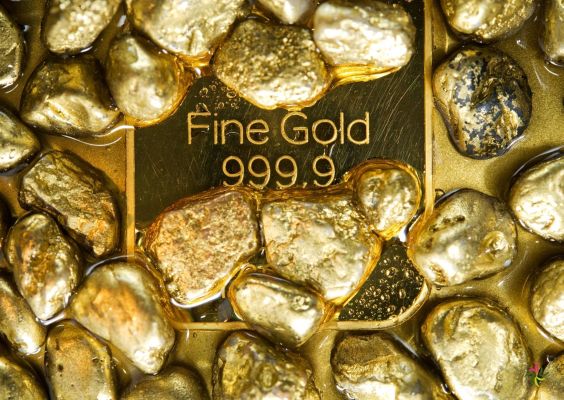

The content of gold alloys is expressed in carats or thousandths. The most commonly used contents are:

24 Carats – 1000/1000 (pure gold)

18 Carats – 750/1000

14 Carats – 585/1000

9 Carats – 375/1000

8 Carats – 333/1000

To comply with 18 carats a deviation of 3/1000 is allowed, i.e. 749, 748 and 747 are still allowed. In order to obtain as little deviation as possible when alloying, when calculating the weight one should round up, when adding one should round down.

Silver

Silver (Ag) is a precious metal with a melting point of 962°C. In its pure state, silver is a very beautiful white metal – the whitest of all metals – which, when polished, acquires a brilliant deep-black metallic sheen.

This shine is caused by 99% of the light being reflected. When it is not polished, it has a matt, white colour.

It is also a soft metal that is very elastic and crushable and the best conductor of heat and electricity, which is why it is also used in fuses and electrical engineering.

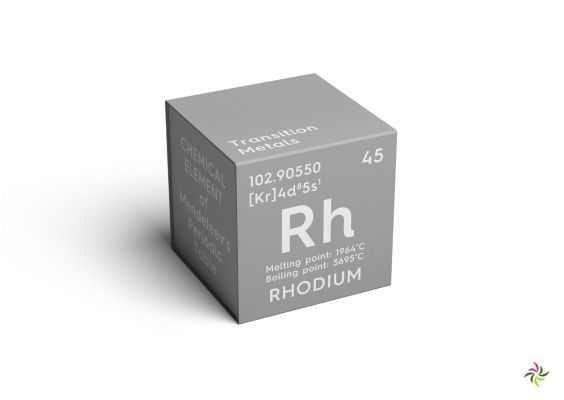

Unfortunately, silver is affected by sulphur in the air and forms a layer of silver sulphide, which is the brownish-black layer that you sometimes see on your silver. This can be avoided by covering the silver – and thus sealing it off from the air – with a layer of rhodium (an extra protective layer to prevent scratching and discolouration).

The content of silver alloys is – just like with gold – expressed in thousand’ths. These are the most commonly used alloys:

999/1000 (pure silver) – too soft for making jewellery / you can bend

950/1000

925/1000 (sterling silver) is used for jewellery

835/1000

800/1000

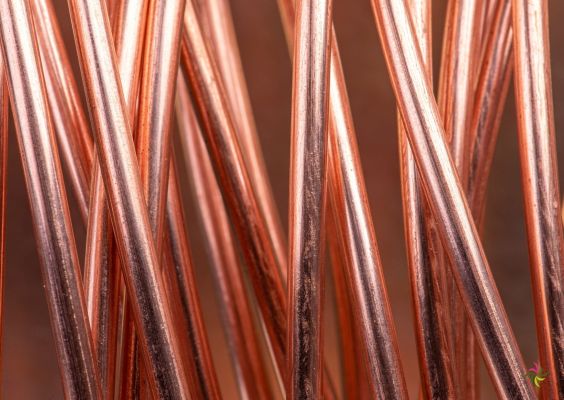

Copper

Copper – also known as cuprum (Cu) – is an alloy metal with a melting point of 1084°C.

Copper is the metal most often used for alloying with pure gold and silver.

The metal copper is also called red copper, to distinguish it from yellow copper, which refers more to brass. In Europe, copper is most commonly used for alloys.

In its pure state copper has a light red colour and a shiny appearance. It is a soft metal that is easy to stretch, crush and bend. Copper oxidises quickly due to humid air and is used as an alloying metal for gold and silver. After silver, copper is the best conductor of electricity and heat and therefore ideal for electrical cables.

Copper increases the hardness of an alloy, which is caused by a chemical reaction between the copper and the precious metal. It also influences the colour of the alloy; the more copper, the redder the metal.

Other alloy metals

Nickel (Ni) has a melting point of 1452°C and is a hard metal with a high resistance to atmospheric influences, meaning that it will not react quickly to humid air. In Belgium it is no longer allowed to use nickel in jewellery because of the possible allergic reactions.

Zinc (Zn) has a melting point of 415°C and is used as an alloying metal for solders and metal alloys, in castings to lower the melting point and as a surface treatment against rust.

Cadmium (Cd) has a melting point of 321°C, oxidises easily and is used as an alloying metal for solders to lower the melting point.

Can the colour of gold be different?

Yellow gold is created by adding copper and silver to the pure gold, but with more silver than copper.

Silver has a whitish colour and therefore this alloy gives gold the colour of yellow gold.

Pure gold has an orangey and somewhat dark yellow colour.

By the way, it is also possible to mix proportionally more copper than silver. In that case the red copper colour predominates and red gold (rose gold) is created.

Mixed gold is an alloy where equal amounts of copper and silver are added to the gold.

White gold is an alloy of gold with palladium, although gold can also be rhodium plated to obtain white gold.

What is electroplating?

Electroplating is a method that uses electricity to coat an object with a layer of metal to make it more corrosion-resistant or shine brighter. The object – which is chemically pure and electrically conductive – is dipped into a solution and then a low-voltage direct electric current is applied. The solution contains a salt of the metal to be electroplated, while other chemicals are added to increase the electrical conductivity and to strengthen the deposit.

Jewellery can be silver-plated, gold-plated or rhodium-plated in this way.

The jewel to be plated is finely sanded and polished until it has reached the desired lustre, as this determines the appearance of the piece.

For a good result, the jewel must be well cleaned, free from tarnish, oxidation and polishing grease.